Today's mission involved getting friendly with GoBILDA's servo mounts and new servos. Before getting started on how to mount these to Tetrix I want to give you a couple of reasons to consider the GB servo's and mounts over the Tetrix ones as I feel they are superior. Flat out the mounts are more sturdy, easier to attach/detach, offer more positions for mounting, and also allow for the use of servoblocks which allow for servos to become a main feature of your robot because they can handle heavy and especially lateral loads easily. In terms of servos lets take a look at the servo specs of a couple regular hiTech servos, if you would like to look at this info here is the link:

https://www.servocity.com/hitec-servo-chart.

Comparing the Servos

So the 2 most common servos I used were 485HB's and 645MG's for light and heavy loads respectively. The 485 costs $17 from actobotics and has 83 oz-in torque @6v(rev hubs don't supply 6v you need the power booster). The 645 is $30 and offers 133 oz-in torque (@6v)

Lets take a look at thee GB servo: its $24 has 200 oz-in torque @6v, faster angular rotation, and all metal gears. In addition it can be converted to a continuous rotation servo with a programmer(Hitech requires a totally different servo). So with almost a huge jump in torque from the 645 as well as lower price and the ability to convert to a continuous rotation servo I think these are the best buy for teams! Keep in mind you will need different horns as the number of splines is different between hitec and GB(futaba spline) Also both GB and Actobotics offer 25% discounts for FTC teams.

Servo Mounts

I have one servoblock from Gb as well as the other mounts available so I decided to look at how they can be interfaced with Tetrix.

ServoBlock Mounting

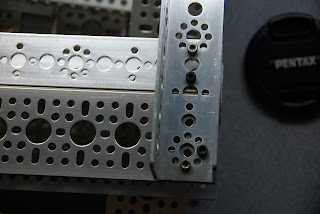

The servo blocks didn't mount quite as easily as I had hoped but it is still very possible to use them. The easiest way to mount them appears to be using the side plates that have an 8 hole GB spacing, this lines up with Tetrix vertically and horizontally, from my picture you can see one way in which it can be mounted, you can simply move and rotate to the other holes for the other mounting options.

The stock base plate is quite hard to mount as the side holes aren't far enough away from the servo to mount to edge tetrix holes. however I found that the two end holes can be mounted to the tetrix as shown, however you must use larger washers or smaller bolts to keep the servo mounting bolts from interfering with the Tetrix. (See right)

The stock base plate is quite hard to mount as the side holes aren't far enough away from the servo to mount to edge tetrix holes. however I found that the two end holes can be mounted to the tetrix as shown, however you must use larger washers or smaller bolts to keep the servo mounting bolts from interfering with the Tetrix. (See right)

I want to point out that servoblocks could be built upon these plates as well. This picture shows how the top assembly would easily move between the mounts. This allows for easier mounting of servoblocks.

(See Left)

Here are some pics of how the other mounts line up. The one with the GB pattern off the end of it is extremely easy to mount as it is just like mounting any piece of GB channel to Tetrix, it lines up in almost every way you want. The other tapped mount is a little more difficult, because M4 screws don't fit through Tetrix. My next post will show you how to remedy that!

You can see in my picture that the top 8 pattern tetrix has been modified, 4 of the holes have been drilled out to accommodate GB bolts. The hole sizes are extremely close already (1/5th mm in diameter) so I don't think there is a problem of actually drilling out ALL of Tetrix channel and pieces etc. to allow for easy mounting all the time, not just when using a tapped feature. As I said before, this would make it so you are using almost all the same bolt and wrench sizes with the exception of maybe motor mounts (you can drill them out too but you would need long m4 bolts). Also for those worried of ruining their tetrix, 6/32 bolts still fit through the enlarged holes and can be used to build a solely tetrix bot.

You can see in my picture that the top 8 pattern tetrix has been modified, 4 of the holes have been drilled out to accommodate GB bolts. The hole sizes are extremely close already (1/5th mm in diameter) so I don't think there is a problem of actually drilling out ALL of Tetrix channel and pieces etc. to allow for easy mounting all the time, not just when using a tapped feature. As I said before, this would make it so you are using almost all the same bolt and wrench sizes with the exception of maybe motor mounts (you can drill them out too but you would need long m4 bolts). Also for those worried of ruining their tetrix, 6/32 bolts still fit through the enlarged holes and can be used to build a solely tetrix bot.